History of Water Event

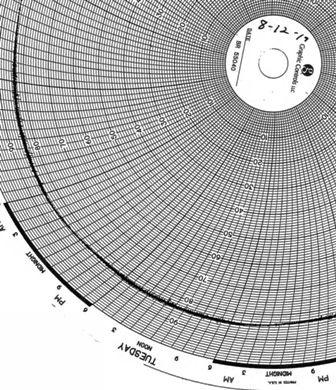

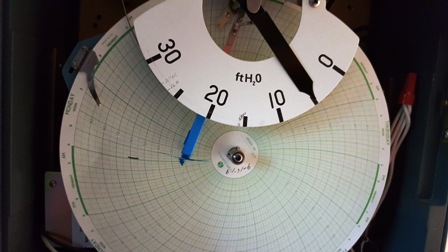

The Canaan Water System uses two methods to monitor water usage and flows. The water level in the 290,000 gallon storage tank is monitored continuously. The flow of finished water from the treatment plant going out into the system is also monitored daily.

Our emergency story started two weeks before Labor Day weekend. Typically, the storage tank runs at about 85% of capacity or 246,00 gallons. Our daily usage runs at an average of 31,000 gallons. So at 85% of our storage, we should be able to rely on stored water for about 8 days.

When a large flow goes out (in excess of 38,000 gallons a day), that can indicate a major event like a leak or a fire that uses a lot of water. The tank shows the on-line reserve and may be increased or lowered on purpose. It may also be kept at lower levels to avoid overflow or manage water quality.

The search for the leak started on Monday, August 12th when it was becoming difficult to maintain the 85% storage level. A single building was discovered to have a documented leak of 291,000 gallons over 150 days or about 2,000 gallons a day. That was resolved by August 18.

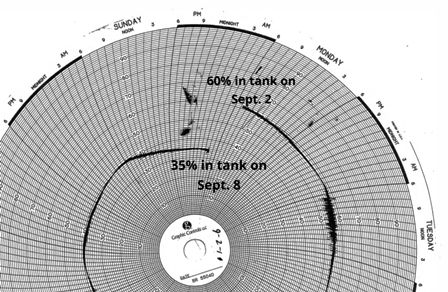

During the week leading up to September 2, the reserve level continued to drop from 85% to 60% or a loss of 15% equaling 37,000 gallons. There were no fire events and the drop indicated another leak.

From Monday, September 2 though September 11, John Coffey, our Water and Sewer Superintendent, checked all unoccupied buildings to see if there were leaks present.

During the week leading up to September 9th, several leaks were discovered. One leak resulted in a loss of 160,000 over 6 days or 27,000 gallons a day that we observed running through our meter. That account was shut off by September 9th but the damage was done.

Our tank was down to 35% capacity in spite of continuously refilling the tank at about 35 gallons per minute. The reduction in reserves from August 26th through September 8th totaled 123,000 gallons in spite of adding an additional 20,000 gallons a day over the normal usage rate. The total loss was nearly 400,000 gallons over the 14 day period. Only 160,000 was accounted for with the leak in an unused building during this search in the first week of September. We were still missing another 240,000 gallons during that same period.

MAXIMUM LOSS WAS 28,571 GALLONS A DAY

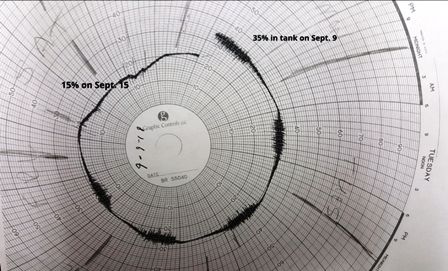

From September 9 through the 12th, our Water Sewer Operator, John Coffey, searched throughout the user system for other possible leaks. John drove the routes looking for surface evidence and found none. By September 11Th, the level had dropped from 35% in the tank on Monday to 30% in the tank on Wednesday. That is a about a 12,000 gallon additional loss. It was becoming difficult to maintain the 30% reserve in the tank.

Thursday, the 12Th, the reserve dropped again to just 20% of the tank. That meant a loss of 37,000 gallons from the tank since Monday the 9Th in spite of continuously adding an additional 20,000 gallons a day.

We had started to suck water from the lake rather than rely on gravity feed to keep the water level up but the pumping started to pick up sediment that was affecting our ability to bring water in. Our ability to increase water dropped from 35 gallons per minute to about 20 gallons per minute.

We decided to take a different approach on Friday. We would be more aggressive in looking for the leak.

Friday, Sept. 13Th, Fire and Highway were brought into the picture. The first suspicion was that the main line from water treatment plant on Fern wood Farms Road had sprung a leak. This line is about 5,000 feet long, is over 100 years old and goes through forest and swamp to get to the Village.

Lebanon Water Department sent two employees over with a listening device to find the main and see if there were any large noises indicating a leak. Bob Scott and Bill Bellion accompanied the two workers and while the route was marked out, nothing was found. The main line splits into two spurs about 1,100 feet north of School Street and there are valves at those locations. Nothing was heard there. Both Friday and Saturday town workers walked through the swampy areas looking for new flows and nothing was found.

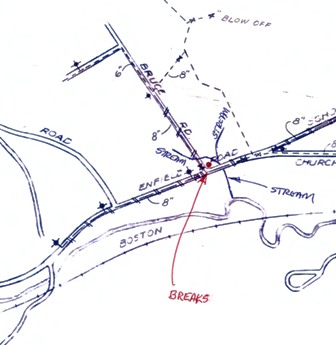

We also started work on closing down sections of the distribution system to see if that impacted the leak. There was some failure in that effort because flows weren't shutting down. It was clear that we had a misunderstanding about some of the valves and water lines. Ultimately, we confirmed that there are 2, 8" water mains that serve the Village that originate in the split 1,100 feet north of the Village.

By Saturday morning, September 14, the level in the tank had dropped to 15%. That was an absolute loss of 63,460 gallons from the tank plus the full time flow going into the Treatment plant.

John tried to increase the flow from the lake by pumping but that started to suck dirt into the lake line. Our water comes from the lake and a well. The lake water goes into a sand filtration system to remove any bacteria, viruses, and suspended solids. Once filtered the water is chlorinated to remove any other bacteria. That treated water is blended with well water and then enters the water distribution system.

With a partially plugged water line to the lake, the plant was only able to process a little over 21 gallons a minute for new water for the 200 units on the water system. The storage tank was filled constantly so we were able to add 30,000 gallons a day. Normal usage is 30,000 gallons a day. We were just maintaining the minimum we needed.

We put users on conservation and issued a boil order because we were sucking dirt and lake debris into the line.

An internal management team of John Coffey, Bob Scott, Bill Bellion, John Hennessy, Phil Neily and Mike Samson was created and responsibilities were assigned.

On Saturday, Sept. 14th, we arranged to bring in Donnie Boynton from Granite State Rural Water, a non-profit that assists public water systems in managing operational issues like leaks. While Donnie is an excellent dowser, he can operate listening devices as well. Donnie started at the furthest in-feed water main leg to the west at Bruce Road. Listening at that location he heard a substantial rush of water. There was no surface evidence of this water. The rushing noise started at the Route 4 intersection on the west side of Bruce Road and worked north up Bruce Road for about 150 to 200 feet.

A survey was completed of all storm drains and culverts that pass under the rail trail looking for running water. None was located other than the stream that comes down both sides of Bruce Road and passes under Route 4 to the River.

A decision was made Saturday to dig west on Route 4 from the gate valve at the end of Bruce Road . The initial digging on the corner exposed a great deal of water. We continued to dig to the west until dark and discovered no additional water flowing back towards Bruce Road.

We also arranged to rent a large portable pump and 1,100 feet of hose to pump additional water from the lake. Highway/Firefighters went to Milford, New Hampshire to get the pump and hose on Friday.

Saturday morning came and the management team split into two groups. One group installed the pump and hoses between the lake and the Treatment Plant. One team focused on leak detection. Because no one was sure about pipe sizes and locations, we had a conversation with the construction firm that built the new line in 1986. Their notes indicated the presence of 2, 8" lines serving the Village. With this knowledge, we were finally able to isolate zones.

The morning was spent with a Hanover employee using a listening device to look for a leak. He also narrowed the leaking area to the end of Bruce Road at Route 4 where we had failed to locate the leak on Friday.

During the afternoon, a fire tanker relay (Enfield and Canaan) filled the tank at the water treatment plant Saturday (about 60,000 gallons).

This water went into the sand filtration beds and was chlorinated before going out into the distribution system and ultimately to the large storage tank.

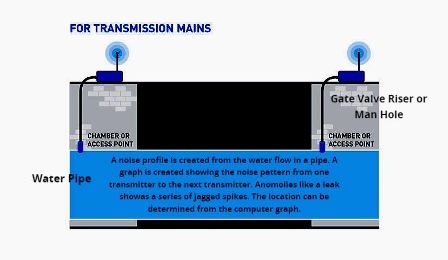

During the early afternoon, we contacted Granite State's Scott Clang for help. Although he has significant health issues (and a Patriot's game), he agreed to bring over acoustic noise profiling equipment that can locate anomalies in water lines at exact locations.

Leak detection is performed by bracketing a section of the transmission main with two magnetic surface mounted sensors, or hydrophones and recording an acoustic noise file. The section of main must be filled with water under normal operating pressure. Leak noise data is captured for each section of the main and uploaded to a computer for analysis.

After three successive tests, the profile identified the exact location of a leak that was on the East side of Bruce Road between Bruce Road and the culvert that crosses under US Route 4. The identification of the leak was completed about 6 PM on Saturday. The hose and pump work was completed about 7 PM.

Water was pumped from Canaan Street Lake over night and and delivered to the water plant through a hose system that the En field and Canaan Fire Departments laid down on Sunday.

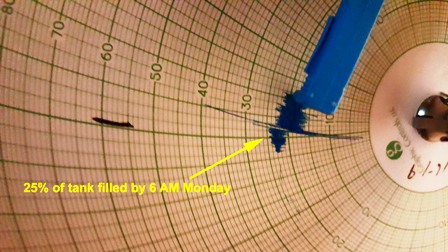

The result was an increase in water reserves at the storage tank from 15% reserve to 25% reserve.

Sunday morning of the 15th, the Highway Department and the Water Department dug up the location of the leak in the water system on the East side of Bruce Road and the North side of Route 4 about 5 feet north of the end of the culvert that passes under Route 4.

By 11 AM, the 8" water main was uncovered and an elbow in the system was discovered to be separated enough to cause a significant leak.

Work started on replacing a section of pipe and the connecting flanges. The bolts holding the sections together were very loose and water was escaping at the connections. It was anticipated that the pipe would be repaired by the end of the day.

The nuts holding the flanges together were very loose.

The pipe showed massive wearing that created holes which is unusual for ductile iron pipe laid in 1986.

At 4:00 PM the water main was pressurized again and a new leak was detected in the Bruce Road area about 15 feet up the pipe towards Bruce Road.

A new section of pipe was installed and the repairs were completed about 9:30 PM on Sunday. The system was re-pressurized without any additional leaks detected.

The system recovered enough to be at a 25% reserve level on Monday. We continue to add water at a 41 gallons per minute rate.

DES and DOT monitored the leak and repairs throughout the weekend.

Due to the work on the line at Bruce Road, there is still some bacteria in the system. It is total coliform and not E. Coli. There is still a boil water in effect. We will review the situation on Thursday morning. Water was taken to Concord for testing Monday and Wednesday.

Replacement Water

Walmart, Home Depot and other donors provided pallets of bottled water. The Town also purchased several pallets of bottled water. Many cases of water were delivered to Canaan Elementary School by the Canaan Fire Department. Bulk water was available at the Mascoma Community Health Center.

Rumors

HIGHWAY

The Highway Department damaged the water main when they replaced a culvert at the end of Bruce Road. Not true. John Coffey monitored the work and the highway crew never came into contact with the water main. The map below shows the water main, the location of gate valve and location of the two leaks.

FLOOD

The damage was caused by the July 11 flooding. Not true. The wear and tear on the pipe was caused over decades, not weeks. Look at the pitting and wear on the 1986 pipe, the pipe appears to have moving in the ground over the past 33 years. This was probably caused by a greater angle in the water line than designed and occurred when installed. The flood saturated the ground by the culvert under Route 4 and may have increased the movement of the pipe during the past two months.

IGNORED THE LEAK

The Water Department searched endlessly for leaks between August 12 and September 12. Two major leaks were discovered and fixed. Those leaks were just as severe as the water main leak. In spite of fixing the first two major leaks, there was no recovery at the tank. All of the hand held acoustic meters were unable to discover the actual location of the leak. The noise of the leak was hidden by the noise of the brook. The leak was found by the equipment that created a noise profile.

SHOULD HAVE FOUND THE LEAK BECAUSE OF SURFACE WATER

Obviously not true with this leak. There was no water on the surface. The water main was covered with 3 or 4 feet of clay that trapped the water down at the water main level which was about 10 feet down.